This is the third installment in a series of blog posts on the oil and gas industry. It will explore topics such as data delivery, trends in the industry and the evolution of oil and gas networks.

This is the third installment in a series of blog posts on the oil and gas industry. It will explore topics such as data delivery, trends in the industry and the evolution of oil and gas networks.

I believe it is safe to say that the demand for energy will never go away. Whether it is fossil fuels, renewable or green energy, we must continue to power everything. The demand for fossil fuels (oil and gas) has never been higher. That means oil and gas companies have a vested interest to search for other oil deposits in areas that seem either too expensive or in a very difficult location.

To move these vast operations to remote areas of the globe, the industry requires a well-trained workforce; however, there is a deficit in these skilled employees. According to reports, this deficit is expected to increase by 2030.

Minimizing this labor gap will be challenging. Faced with this situation, oil and gas companies are looking at a different strategy: re-engineering the traditional labor-intensive industry into modern, technology-driven “digital oil field” that requires only a handful of skilled people.

Energy companies are constantly pursuing ways to improve production control and efficiency. Over the years, those companies who integrated the digital oil field concept into production and exploration saved hundreds of million dollars every year.

A couple of oil company that have deployed digital oil field initiatives are Shell and BP. The projected spending on oil field digital investments is more than US$1 billion over the next few years.

A commonality for all these digital oil fields is the “what” and “how” they gather and analyze data throughout the site. This includes the following:

- Remote, real-time facilities and monitoring control

- Intelligent wells

- Smart, connected pipelines

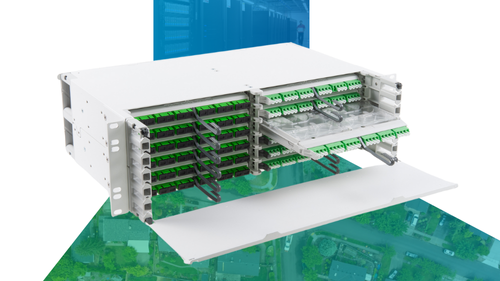

In almost every case, an interconnected architecture is used with fiber-optic cables connected to sensors that are controlled by operators or automatic through closed-loop information systems. These sensors transmit a constant stream of data through the environment, enabling operators to respond to shifting events in real time. As the global energy market becomes more complex and demanding, it will require an advanced data-driven modeling to improve its forecasting capabilities.

Any of those environments requires ubiquitous connectivity to help them plan and direct their way to the next-generation energy mix. This includes the following:

- Tracking and managing environmental impact

- Remote monitoring of increasingly complex equipment in real time

The use of advanced data asset management capabilities provides energy companies with access to new, real-time data and analytical capabilities, and trends. This can overwhelm them with an unprecedented mass of “big data”. By leveraging advanced analytics powered by supercomputing capabilities, energy companies can increase oil field performance and site production.

SEE ALSO: Physical Layer Relevance In The Oil And Gas Market

While the economic contribution of oil and gas transportation and storage infrastructure investment is significant, it is important to recognize that these investment levels are clearly not as large as the capital expenditure elements related to the conventional and unconventional oil and gas sector. It is necessary to take into account the infrastructure needed to bring the upstream products to market passing by midstream and downstream sites.

Deploying technologies like TeraSPEED, LazrSPEED multi-mode fiber, an Automated Infrastructure Management system and DCIM can enhance productivity, address the demands of energy assist with data asset management and the whole oil and gas operations cycle. This is what a trusted technology advisor like CommScope can do for the entire energy market.

SEE ALSO: CommScope Solves Network Challenges In The Oil And Gas Market